PRODUCTION OF MACHINES FOR METAL INDUSTRY

Metal industry

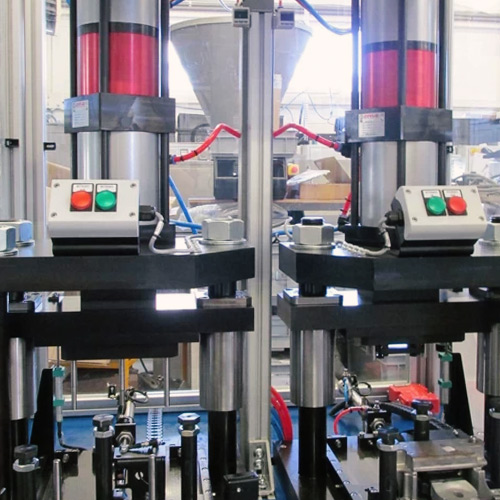

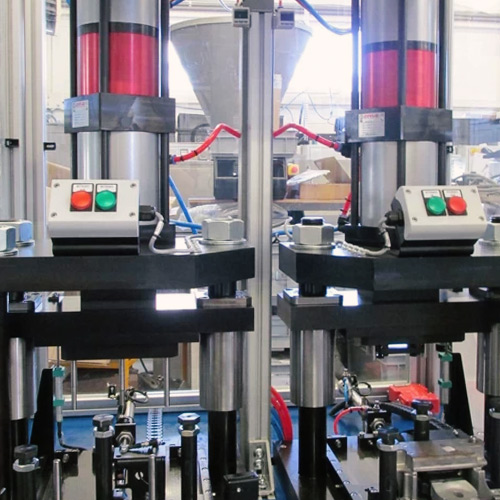

For this industry we manufacture semi-automatic assembly stations, automatic assembly machines equipped with the control or measurement systems.

We create assembly and testing equipment. We build individual stations for metal component assembly using the methods specified by the customer. Assembly operations include riveting, tightening, press-fitting and other.

Workpiece tests

We manufacture assembly stations, testing and inspection machines, and special equipment related to the production process. We deliver complex laboratory-grade measurement stations, as well as simple instruments to support the employee during the assembly.

We build automatic assembly machines supported on 4- and 6-station turntables for the assembly and packaging of metal components. These systems are semi-automatic equipment for manual loading of components to the assembly socket equipped with safety barriers and discharge chute assembly with good/defective product selection.

We manufacture programmable sheet metal punch cutting equipment consisting of the unwinding system and the multi-tool intelligent punching press.

Scope of services

In cooperation with the TRUMPF company, we are ready to implement the production laser marking system in your company (laser marking machines).

The assembly equipment we manufacture is very often fitted with measurement and control systems: the typical application of the auto-test is to check the force and displacement relationship during the assembly process (force and travel control). The assembly machines manufactured by PROMATIK are equipped with pre-assembly component lubrication systems. This is lubrication based on an oil mist fed to the tool or solid grease spot-applied on the components directly before the assembly.