AUTOMATIONS FOR ELECTROTECHNICAL INDUSTRY

Electrotechnical industry

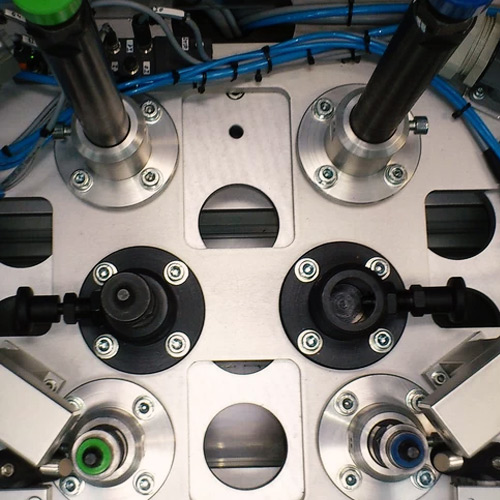

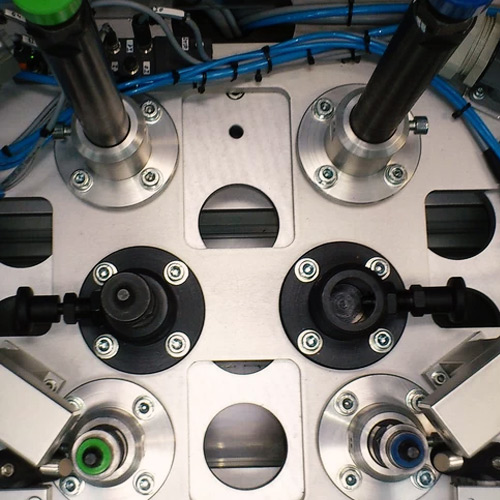

We build automatic assembly machines based on 4- and 6-station turntables for the assembly and packaging of electrical components. These systems are semi-automatic machines for manual handling of components to the assembly centre, provided with safety barriers and a discharge chute assembly for OK/NOK product classification.

We also provide unmanned devices for assembly of electrical contacts. The devices usually comprise vibrating feeders and assembly tooling units. The assembly is most often done by bolting, press-fitting, riveting, or crimping.

Workpiece tests

We manufacture programmable sheet metal punch cutting equipment consisting of an unwinding system and a smart multi-tool punching press. We produce auxiliary workstations for simple assembly operations done by operators. In cooperation with the TRUMPF company, we are ready to implement a production laser marking solution (laser marking machines) at your company.

Scope of services

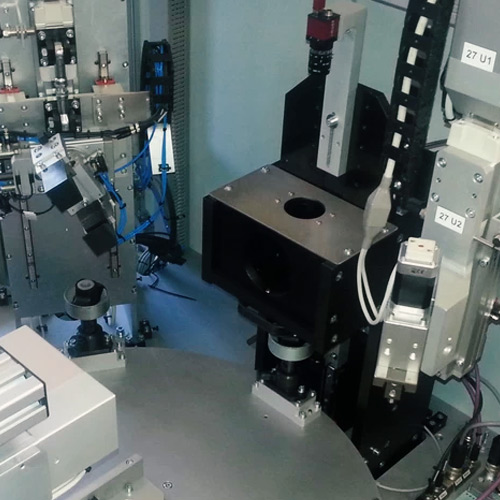

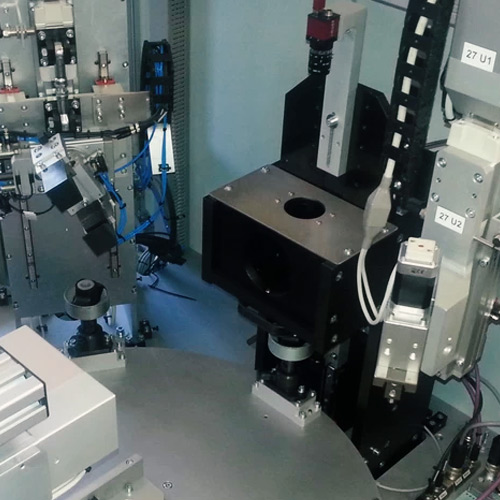

The typical inspection stations we manufacture for the automotive industry include machines for:

- Operating torque and angle of rotary switches;

- Performance testing (resistance and position) of pot-meters;

- Functional testing of products with permanent marking;

- Dimensional and assembly completeness checks of finished products and micro-impact (datamatrix) marking application, complete with printing of inspection stickers for the customers;

- Electrical testing of electronic circuits: current and voltage tests, electric transition tests, resistance and insulation testing, and dielectrical testing;

- Leak testing (by leak amount measurement) of finished components, with durable product marking (by application of inkjet printers);

- Leak testing (by volume/pressure loss in sealed vessels) of finished components and permanent marking of the product (by application of inkjet printers);