Equipment for the automotive industry

Automotive industry

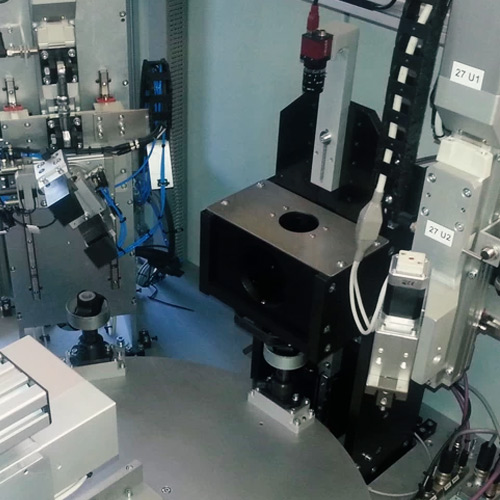

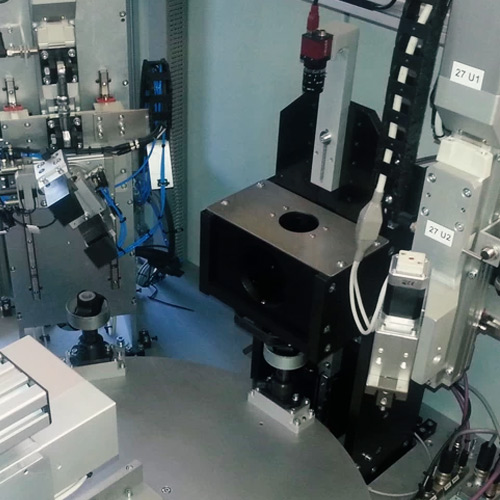

The typical stations we manufacture for the automotive industry notably include assembly equipment with:

- Automatic tightening components equipped with angle and torque measurement (we use DEPRAG, BOSCH, ATLAS COPCO, GEORGES RENAULT, DOGA),

- Radial (orbital) riveting machines, rotary riveting machines with simultaneous single- or multiple-point riveting (preferred supplier of riveting machines: BALTEC),

- Machines for the assembly and auto-test of tightness of the components after assembly

(based on ATEQ apparatuses), - Assembly machines for press-fitting, crimping, the so-called toxing, pressing and other operations related to the process of the customer.

Workpiece tests

The typical control stations we manufacture for the automotive industry notably include units for:

- Checking the operating torques and angles of automotive rotary switches (BURSTER, STEIGER MOHILO);

- Measuring the operating characteristics (resistance-position) of automotive potentiometers (RESISTOMAT);

- Functional testing of the product and permanent marking of the product;

- Checking the dimensions and completeness of the finished product and checking the micro-impact marking (LEUZE or COGNEX datamatrix) and printing self-adhesive label for the customer (ZEBRA);

- Electrical measurements of electronic circuits, electric current and voltage measurements, electric transition tests, resistance and insulation parameters control, dielectric test (tests performed using in-house built components);

- Testing the tightness (by checking the ATEQ leakage values) of finished components and permanent marking of the product (METRONIC inkjet printers);

- Testing the tightness (pressure drop in closed container – “volume”) of finished components and permanent marking of the product (METRONIC inkjet printers);

- Functional testing of the product in the final version, checking the completeness of assembly and laser marking using marking machines by SUNXPRODUKCJA STANOWISK DLA BRANŻY AGD.

Scope of services

We create assembly stations and auxiliary equipment for the assembly process.

- Automatic tightening components equipped with angle and torque measurement (we use DEPRAG, BOSCH);

- Radial (orbital) riveting machines, rotary riveting machines with simultaneous single- or multiple-point riveting (preferred supplier of riveting machines: BALTEC);

- Machines for the assembly and auto-test of tightness of the components after assembly (based on ATEQ apparatuses),

- Assembly machines for press-fitting, crimping, the so-called toxing, pressing and other operations related to the process of the customer.

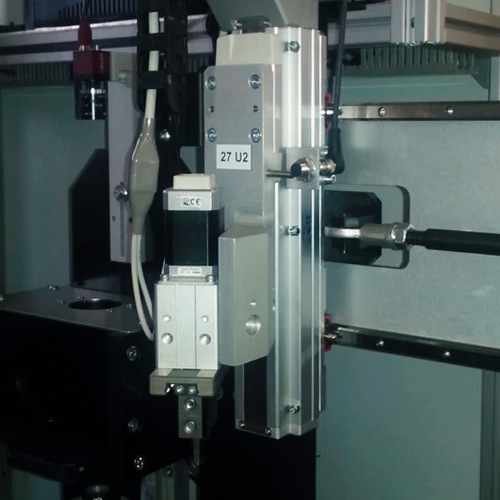

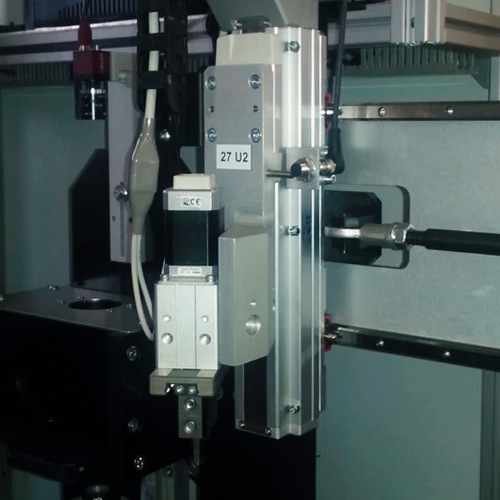

The assembly equipment we manufacture is very often fitted with measurement and control systems: the typical application of the auto-test is to check the force and displacement relationship during the assembly process (force and travel control). For example, testing applications use:

– testing the tightness (by checking the leakage values) of finished components and permanent marking of the product (inkjet printers);

– testing the tightness (pressure drop in closed container – “volume”) of finished components and permanent marking of the product (inkjet printers);

PROMATIK transfers automated process lines from the factories located mostly in Western Europe to the factories in Poland. We undertake projects of relocation of automated production lines to Poland. Such tasks are completed by our team of mechanics, electricians and automation engineers.

We also provide a functional check of equipment before transfer, line disassembly by our own means, supervision over the loading at the source site by the customer, supervision over the unloading at the destination site, assembly by our own means and start-up and initial start-up test by our own means.