WHY ROBOTS?

▮24H PRODUCTION

▮increasing Production Rate Accuracy

▮WORKING WITH DANGEROUS PRODUCTS▮

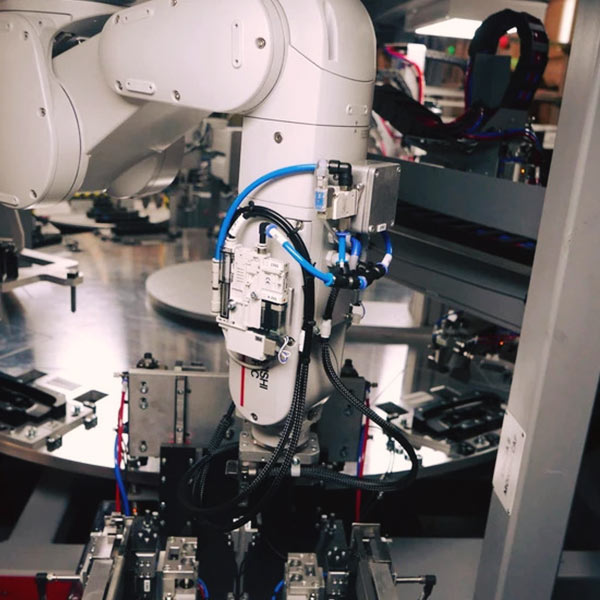

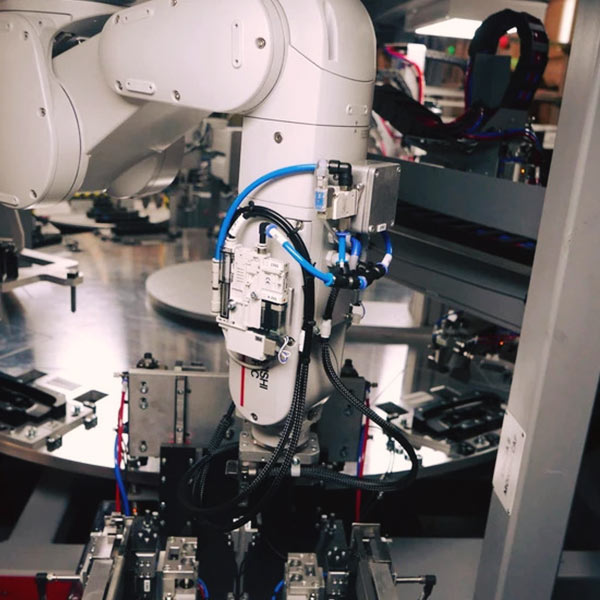

Robotics

The robots are used not only in resource-intensive industrial applications, but also to protect work processes and labour replacement. It is very difficult to give typical costs of robot applications due to the diversity of applications. There are many examples however, in which the robot application cost is only EUR 1.60 per hour.

Robots are successfully used in various places, for example to relieve people: handling hazardous products; performing monotonous tasks; performing works in tight spaces and improving production capacity: increasing production precision; performing production 24 h/day; reducing downtimes.

The product range of PROMATIK includes the following robot applications (robotised stations):

Placement of parts, cooperation with the video system.

We offer to design and implement the robotic unit consisting of a feeder discharging parts in a disorganised manner on the conveyor belt; a video system recognising the presence, coordinates and orientation of parts; the SCARA robot transfers and places parts for the further process stage (automated line or processing socket). The video system and synchronisation with the instantaneous speed of the belt conveyor, the so-called tracking.

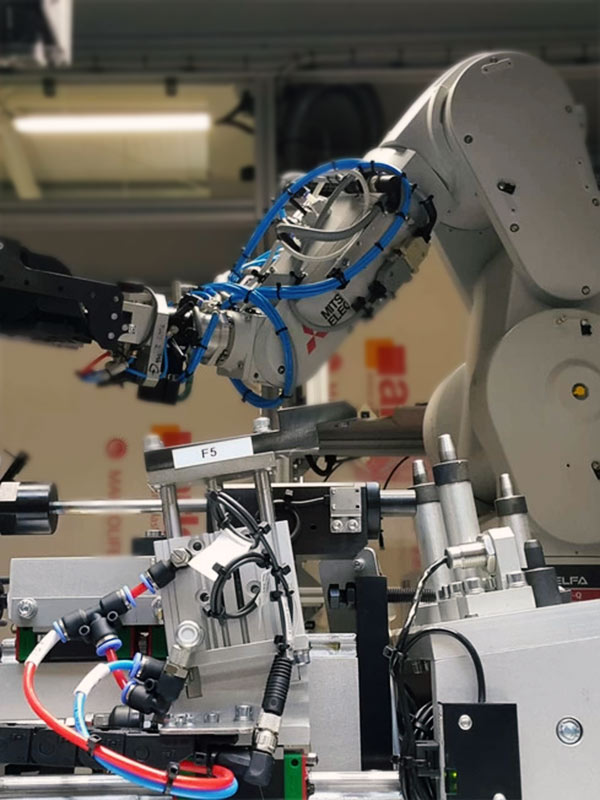

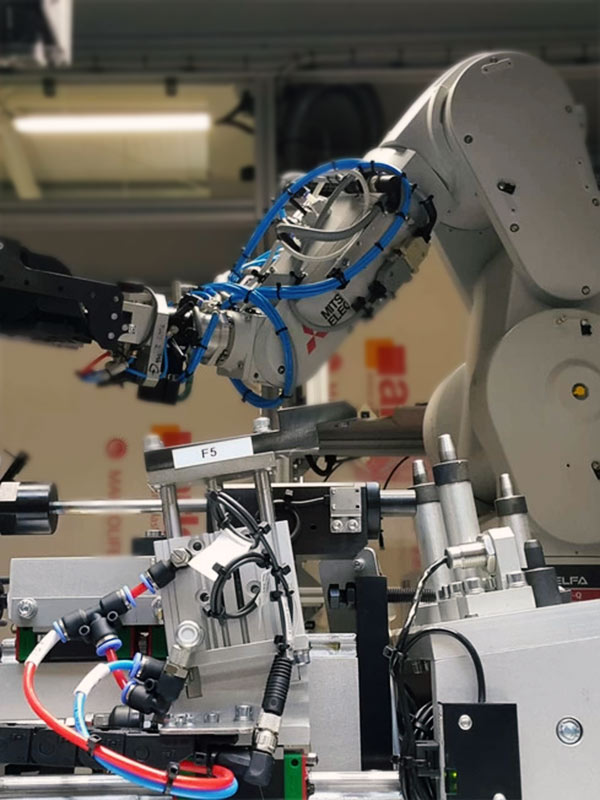

Sealant, adhesive application.

We propose to automate the production process, during which you must apply various types of sealant, “silicon” or paint on the surfaces of your manufactured products. We offer to design and implement a robotic station that ensures the automated application of sealants, adhesives or resins on the casings of household appliances, car lamps and other.

Unloading, packaging, palletisation.

We offer to design and implement a robotic unloading station that receives parts from the automated line and places them in collective packages, for example boxes. Such applications can also ensure the so-called palletisation, that is the placement of parts on trays or in containers in an organised manner.

Placing parts in the machine tool or injection moulding machine.

We offer to design and implement a robotic station feeding the material to the processing machine or directly to the socket of the injection moulding machine. Such unit can be equipped with a system of vibrating and belt feeders of small parts.